What is Peb?

In conventional systems a single section big enough to compensate for the maximum stress is used while different stresses occur at each point of the frame constituting the building. This situation adds unnecessary weight on the building; increases the earthquake load falling onto it as well as increasing its cost and reduces building’s elastic mobility.

PEB system arose from the need for removing such disadvantages of the abovementioned conventional system.

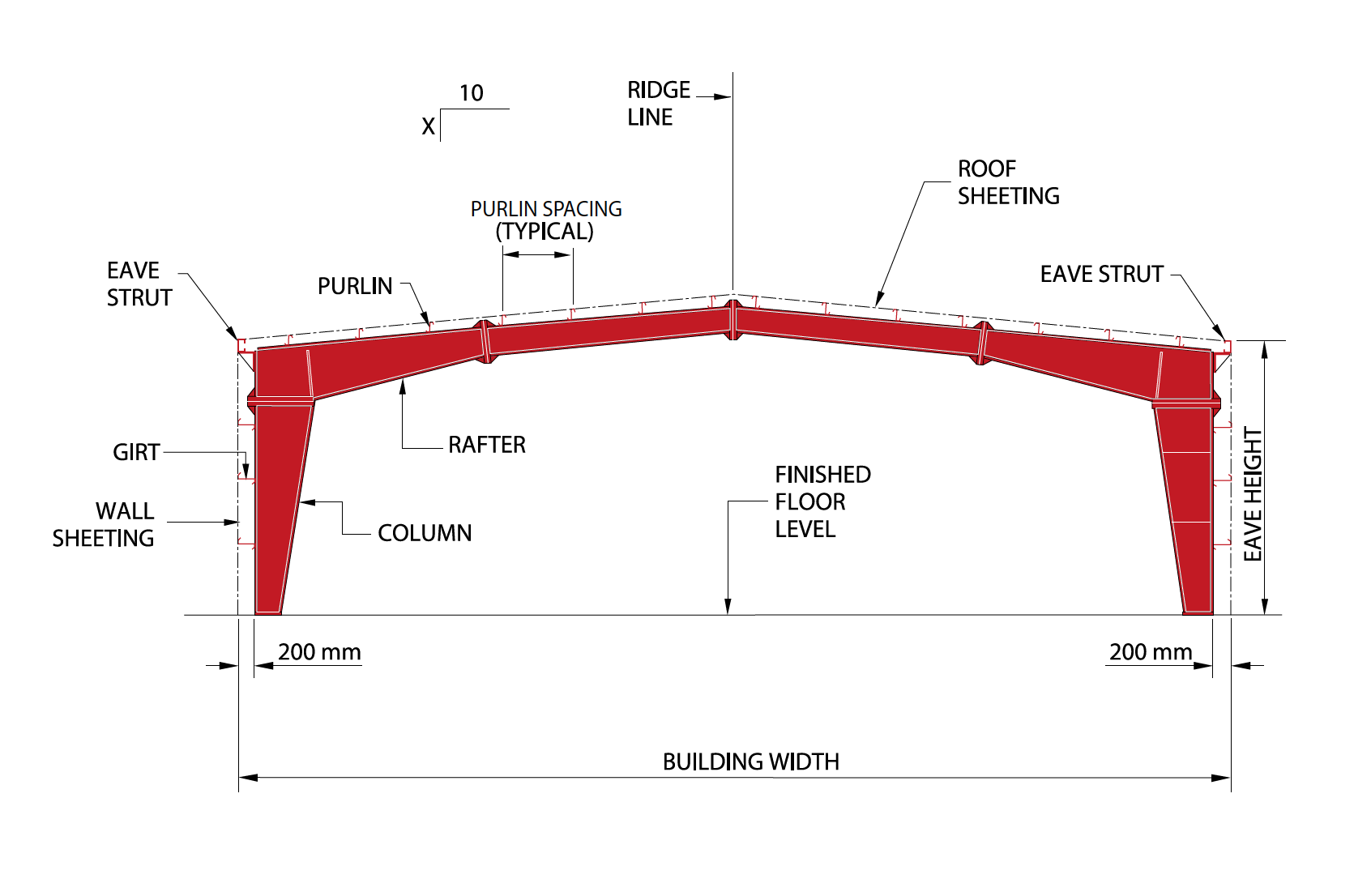

PEB is a modern building design system which sets forth the production of artificial profile sections in various sizes according to the capacity needed by construction elements by taking as a basis the fact that stress concentrations vary in the system constituting the building.

This system lightens the building, provides it with an elastic and economical structure and removes the dependence on ready-to-use profiles.

Advantages;

Cost: Peb system is rather economical in comparison to conventional systems. As agreements are made according to turn-key principle, it doesn’t cause employers any unexpected costs. Cost reduction is not limited to steel constructions; infrastructure (foundation concrete, excavation etc.) costs are also reduced dramatically. No welding works are applied in the construction site. All joints are bolted. In case of any need, construction materials can be removed and used for other projects. This is a cost-reducing factor as especially the buildings which are used for a short period can be made use of in many other projects. Besides; as projects and relevant details are prepared by the producers, deducting design costs will also reduce the total cost amount.

Instant Installation: Installation period is very short as all products are bolted. This time reduction is a general cost-reducing factor for employers.

Recycling: Recycling duration of this investment is much shorter in comparison to other systems.

Strength and Safety: Sustainability of the buildings is ensured for long years without much maintenance need as all secondary steel elements are galvanized, primary elements are sandblasted and painted in the factory and all steel elements are prevented from being exposed to damp, condensation and corrosion thanks to the use of proper isolation systems. In addition, the unnecessary steel elements used in conventional systems make buildings heavy. As is known, earthquakes’ impacts on the buildings are directly proportionate to their masses. Earthquakes’ impacts reduce at the same rate as buildings get lighter. At the same time, buildings’ being unnecessarily heavy causes them to exceed ground bearing capacity. As unnecessary heavy profiles are used in conventional systems, more stress concentrations occur on joints. No matter how heavy is the profile you are using, a building’s safety is indexed to the success of the foreman welding under difficult conditions at the joints, on a ladder. In short, it is indexed to human factor. If any defect occurs in the welding applied to joints, the system may come to the brink of collapsing because of the junctures occurring in these areas. In PEB system, all welding works are performed in the factory with robots and under the control of welding foremen. As buildings are light, the stress concentrations taking place on joints are reduced. Safety is not indexed to human factor any more since all joints are bolted.

Working Safety: Duration of the installation works performed on the construction site which is under employers’ responsibility will be reduced, become practical and risk of work accidents will be minimized as 90% of the manufacturing period is completed in factories, all joints are bolted (not welded) and not even painting works are not performed on the construction site.

Low Maintenance and Operation Costs: Maintenance and operation costs of the buildings constructed with this system are rather low in comparison to other conventional buildings. Buildings maintain their new appearance for many years. They can even be removed and used in other projects.

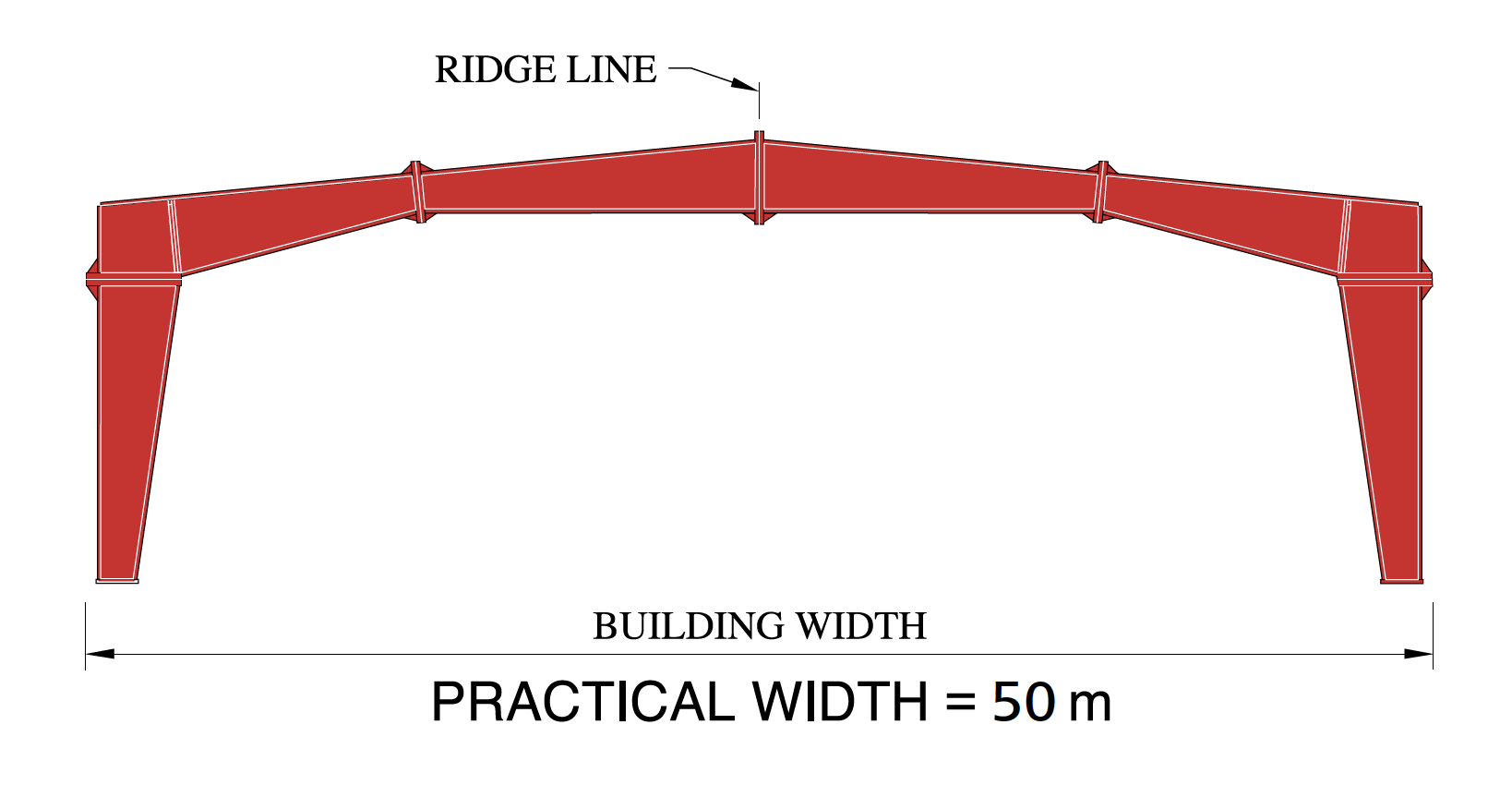

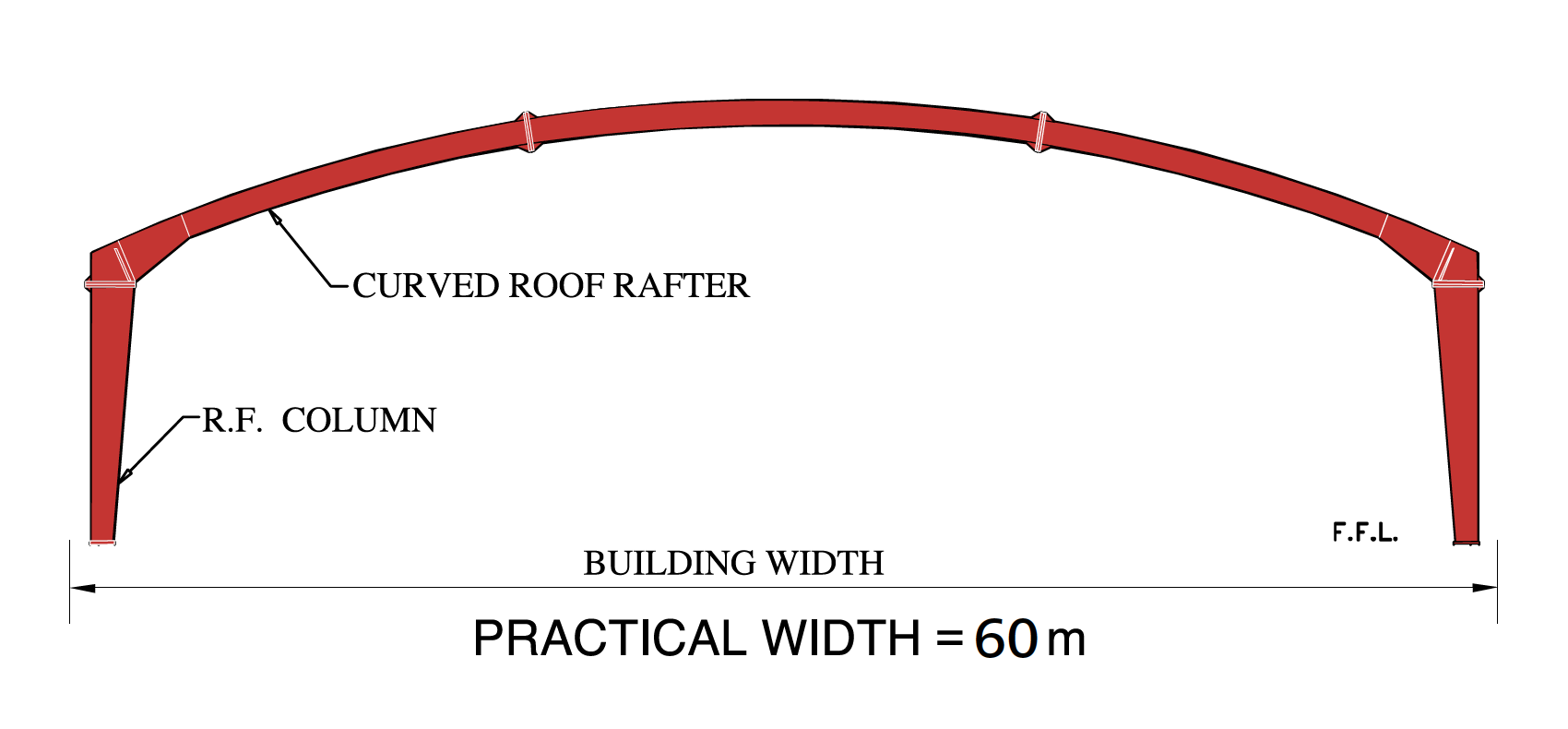

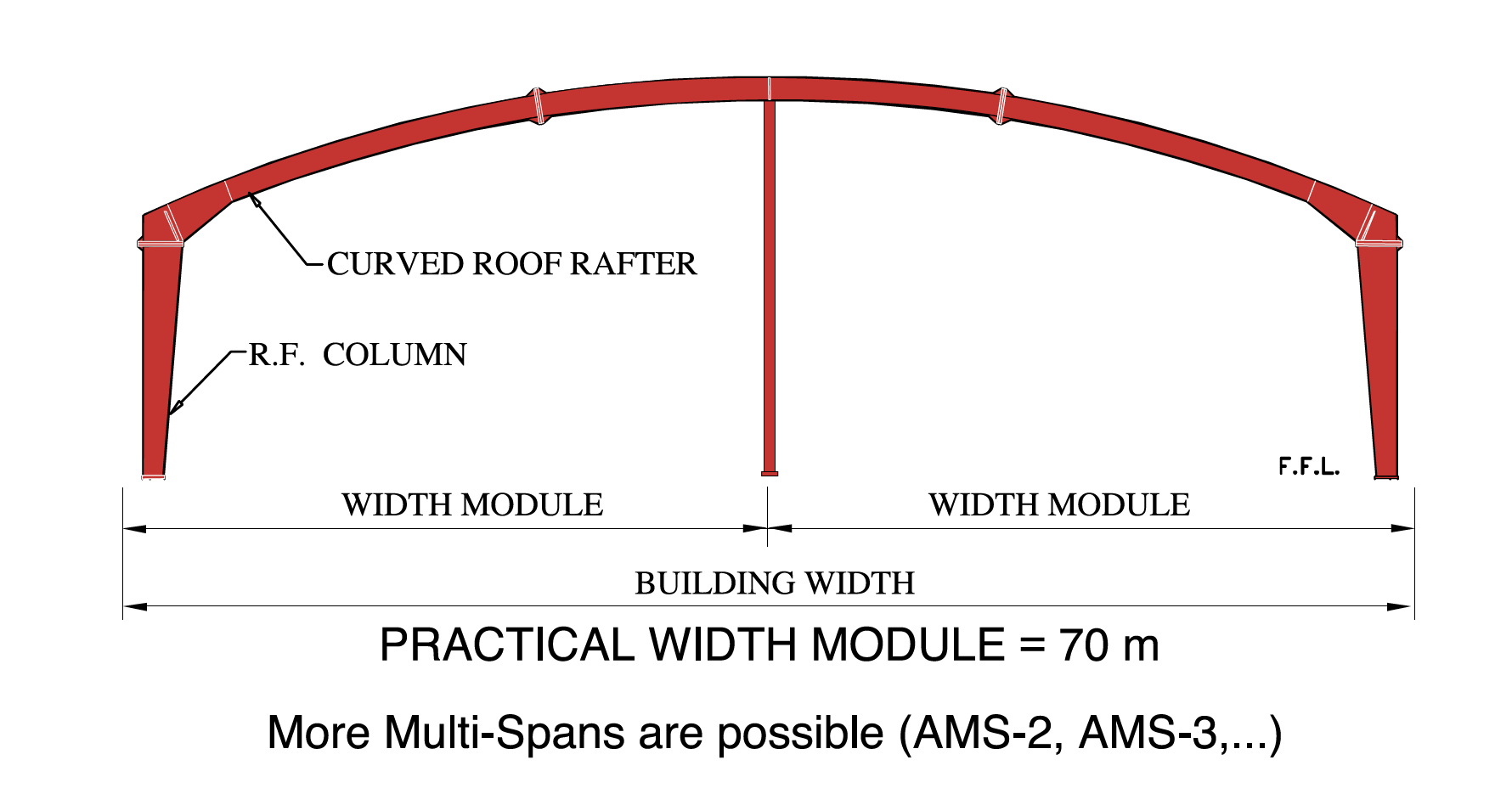

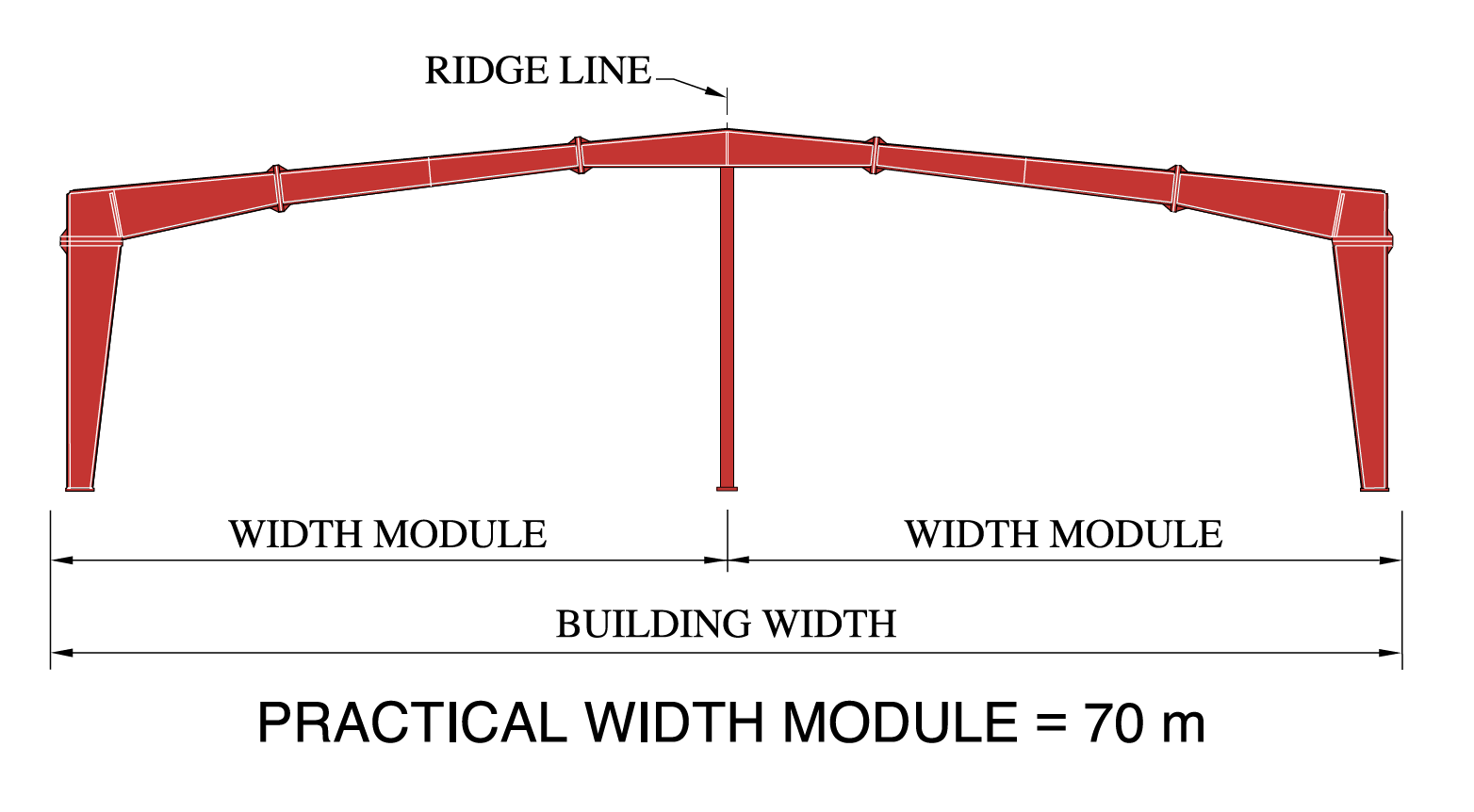

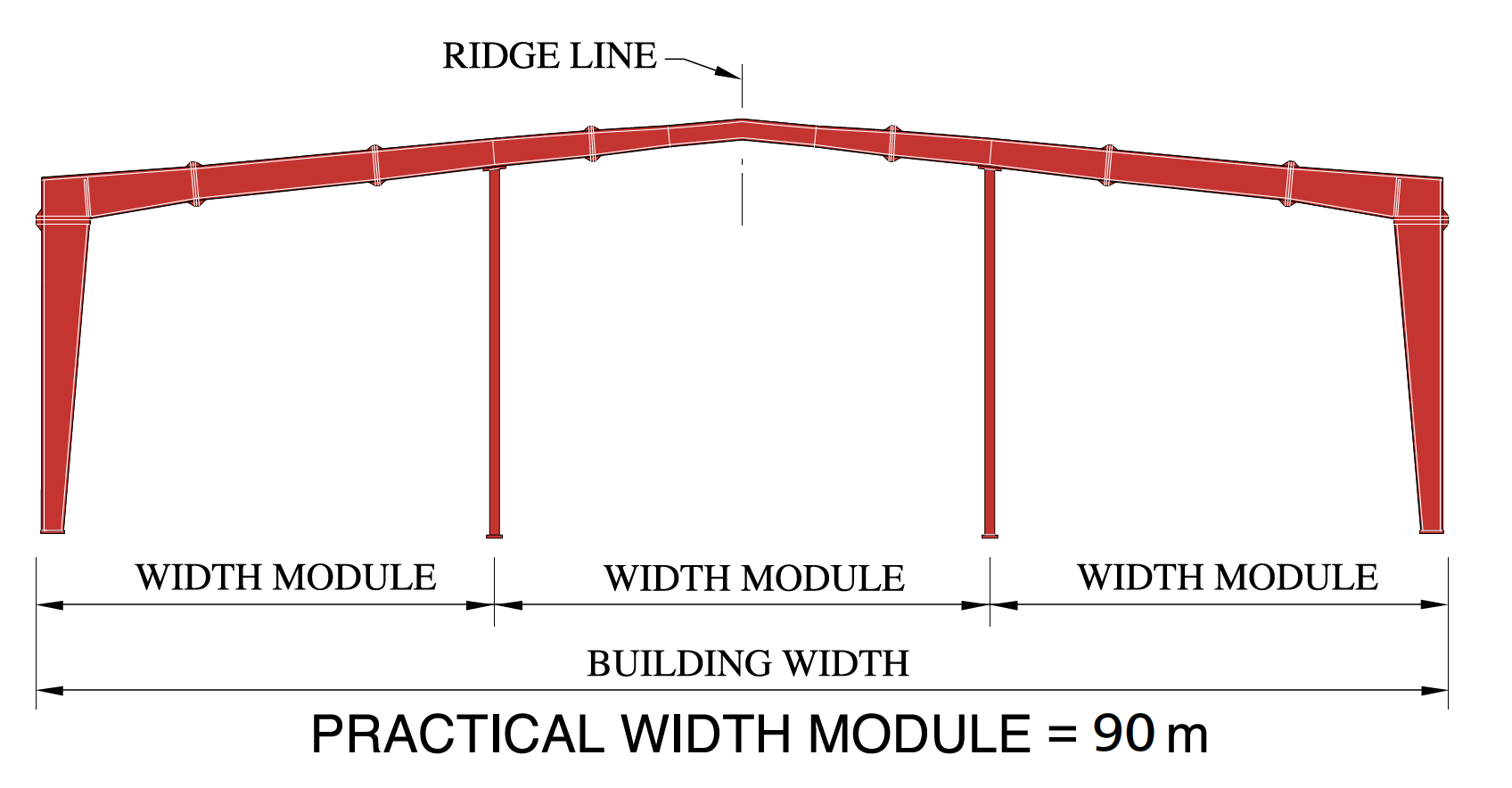

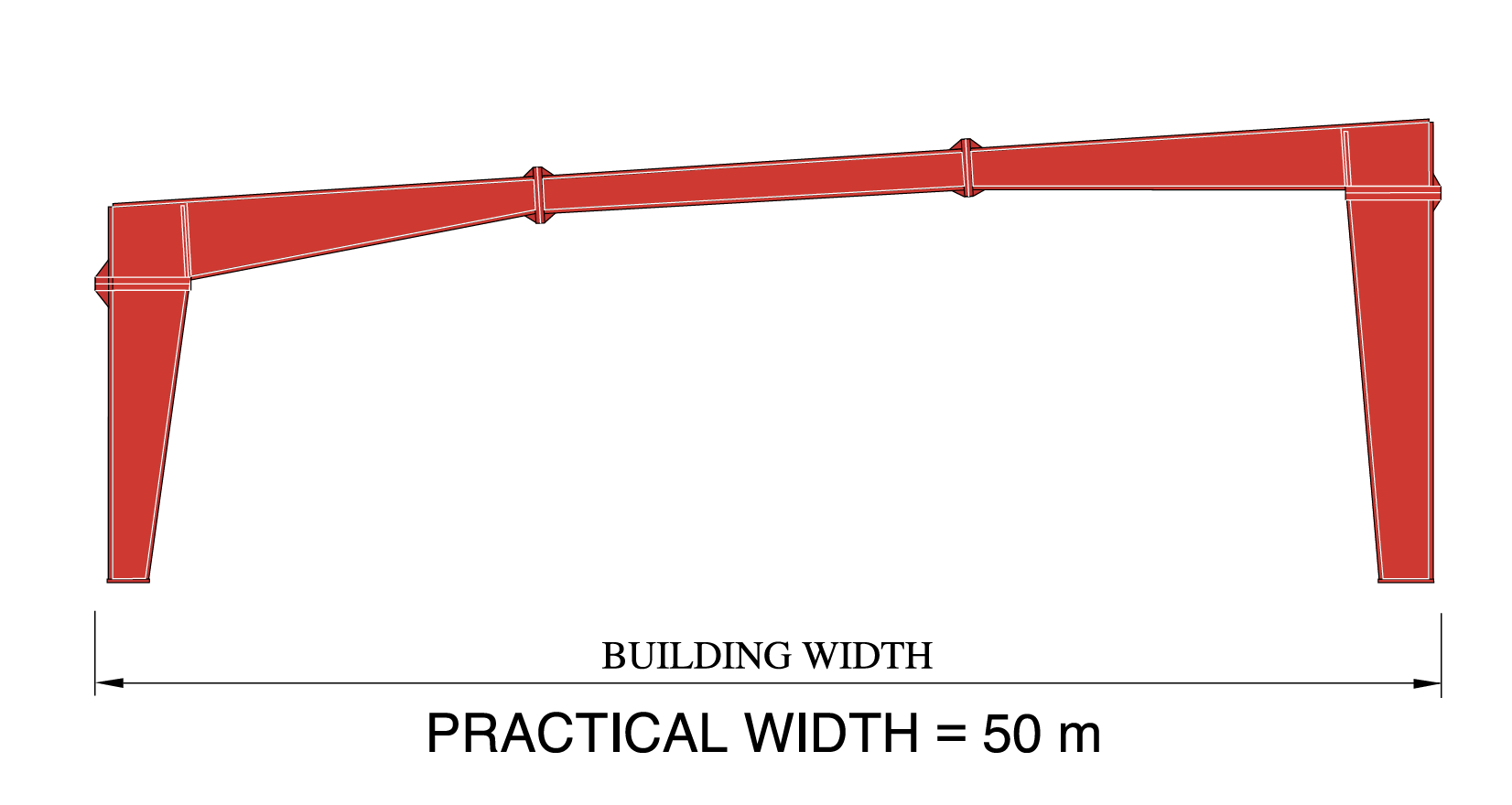

Versatility and Architectural Design Flexibility: In PEB system, single storeys and mezzanines can be designed in the required roof type, session, space and height according to employers’ needs.

Energy Saving: As the isolated materials and secondary steel elements used in buildings are designed to block air bridge, in summer hot air and in winter cold air are prevented from affecting buildings. At the same time, they don’t allow moisture and damp formation in indoor area; prevent unnecessary energy consumption.

Longevity: You can be sure that you will have a building which will exist for long years thanks to high quality metals and joint elements.

Environment Friendly: 90% of the materials used in PEB system can be recycled.

- Oruç Reis Mah. Vadi Cad. İstanbul Ticaret Sarayı No:108 İç Kapı No:543 Esenler/İstanbul

- +90 212 351 12 40

- alsy@tolay.com.tr